Traditional Food of India

2.2.Idli

The traditional fermented rice cake idli or idly (Indian rice cake), though originated in the Southern part of India, is now popular throughout India and neighbouring countries (Figure 2.2.1). The size of a conventional idli is about 75-100 mm in diameter while the thickness varies between 10 and 20 mm. The central part of the idli is thicker while tapering at the end of the circular shape. The advantages of idli are low in fat content and easily digestible. The low shelf-life of only a few hours is a limitation of the product. Idlis are consumed along with sambar and coconut chutney (a thick paste conventionally prepared by wet grinding of puffed Bengal gram, coconut pulp and green chilli) as the breakfast food; a vegetable curry is sometimes used.

Raw materials

Parboiled rice and black gram are the main ingredients for idli preparation. Minor and optional ingredients are salt, ghee, curd (dahi), cumin, black pepper and mustard seeds, turmeric powder, and other grain flours. Special idlis may contain pieces of fine or medium-sized wheat semolina, pieces of chilli and carrot, and roasted nuts like cashew nut and groundnut, etc.

Method of preparation

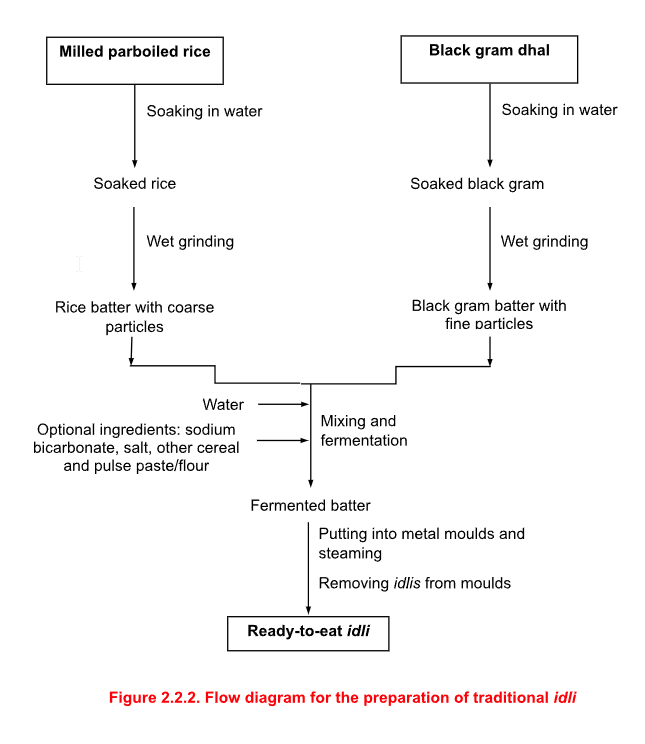

A mixture of water-soaked rice and black gram (urad dhal) flour batter is allowed to undergo auto-fermentation (Figure 2.2.2). The time for fermentation is typically 6-8 hours at ambient temperature. Then the batter is put into the metallic moulds and subjected to steam cooking at ambient pressure for 10 to 15 minutes. The gas produced during the fermentation process escapes during the steaming process and thus marginally expanded soft-textured spongy ready-to-eat white product is obtained. Idli is traditionally a breakfast food though it can also be used during meals along with sambar, a legume-based cooked thick or thin liquid sample. The proportion of rice (high amylose-containing varieties preferred) and decorticated black gram flour is typically 2:1 though other proportions like 3:1 and 4:1 are also in use. The rice sample used is moderately coarse ground raw or parboiled rice, or a mixture of both. The black gram dhal is wet ground to a fine paste. The wet ground batters are then mixed well along with a small quantity of salt followed by fermentation.

The soaking process of rice and black gram is performed for a few hours, mainly to hydrate the samples and soften them to help the next grinding step. The amount of water required to prepare the batter of desirable and uniform consistency is carefully adjusted. In traditional practice, rice grain and black gram dhal are separately wet ground employing a hand-operated stone grinder in the houses, while an electricity-operated grinder is in use in several places where a large number of idlis are prepared and served. The ready-to-use batter and instant dry mix of idli are available where the lengthy process of fermentation can be avoided.

Special varieties

Rawa (wheat semolina or sooji) based idlis with vegetable pieces are available. Thaate (plate) idli is a large idli of the diameter like a plate; the diameter of the product is 150 to 200 mm and thickness is about 15-20 mm. This flat idli is shaped like a flat disc and hence is called thaate idli. Special varieties of idli are also made with green gram, ragi, flaked rice, tapioca globules, etc. A small-size idli, called mini idli, is sometimes used as a special variety. Idli fry is a delicacy where the pieces of fried idli samples become crispy and shelf-life increases.

Technical data

- The development of continuous idli-making machines has been reported. The resultant product idli is served warm along with compatible traditional culinary dishes such as chutney and sambar.

- The rheological status of idli batter has been reported to be non-Newtonian shear-thinning with yield stress. The suitability of rheological models is available.

- The physiochemical and microbiological changes during idli preparation have been studied. Usually, the microorganisms involved are acetic acid bacteria and yeasts. Two significant changes occurring in idli fermentation are acidification and leavening of the batter. The pH decreases from an initial value of 6.6 to 4.5.

Machinery

A wet grinding unit, batter mixing device, batter dispensing system and a batch steaming unit are needed.

Requirements

- During storage, the texture of idli is significantly affected and a harder product results that can adversely affect consumer acceptance. Research investigations may focus on maintaining the desired quality attributes of idli for a longer time and increasing its shelf-life.

- A compact design of a continuous idli-making machine of moderate capacity like 100 to 200 idlis/hour will help catering services like restaurants, industrial canteens, and fast food outlets.

- Development of ready-to-eat idli may be attempted to offer maximum convenience to the consumers.

- Frozen idli may be considered for commercial marketing and export as a health food.

Further reading

Bhattacharya, S. and Bhat, K.K. (1997). Steady shear rheology of rice-blackgram suspensions and suitability of rheological models. Journal of Food Engineering 32, 241-250.

Murthy, C. T. and Srinivasa Rao, P.N. (1997). Thermal diffusivity of idli batter. Journal of Food Engineering 33 (3-4), 299-304.

Rati Rao, E., Vijayendra, S.V.N. and Varadaraj, M.C. (2006). Fermentation biotechnology of traditional foods of the Indian subcontinent. Chapter 3.18. In: Food biotechnology, 2nd edition. Edited by Anthony Pometto, Kalidas Shetty, Gopinadhan Paliyath and Robert E. Levin. Taylor and Francis, Boca Raton, USA.

Tamang, J. P., Thapa N., Bhalla, T.C. and Savitri (2016). Ethnic fermented foods and alcoholic beverages of India. Chapter 2. In: Ethnic fermented foods and alcoholic beverages of Asia. Edited by Jyoti Prakash Tamang, Springer India, pp. 17-72.

Websites